|

Dr.

Kalpana S. Katti

Dr.

Dinesh R. Katti

Back to research pages of:

Dr. Kalpana

S. Katti

Dr.

Dinesh R. Katti

TV Interviews

June 2005

(9 MB)

Fall 2002

(6 MB)

|

|

PRINCIPAL

INVESTIGATORS

|

|

Dr.

Kalpana S. Katti

Dr.

Dinesh R. Katti

Department of Civil Engineering

North Dakota State University, Fargo, ND, USA

|

|

RESEARCH

OBJECTIVE: To develop multiscale models for predicting mechanical behavior of biological materials by bridging molecular, nano to macro scale mathematical models.

This research answers fundamental reasons for the extraordinary mechanical properties

like toughness and strength exhibited by biological nanocomposite nacre, the inner layer of seashells.

|

|

|

| |

|

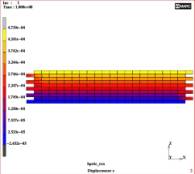

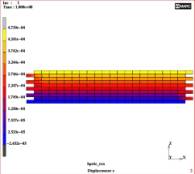

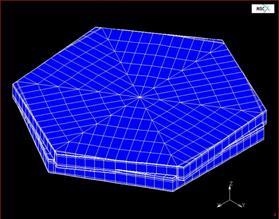

3D Finite Element Simulation of Nacre Micro-Architecture

: Laminated

Structure: Inelastic Response

RESULTS: The purely laminated

structure of nacre as widely proposed would require the organic phase

in nacre to have an extraordinarily high yield stress of 400 MPa. (Our

discovery of platelet interlocks in 2005 will eliminate this

requirement - see below)

Katti, D. R. Katti, K. S., Sopp J., and Sarikaya, M., (2001)3D Finite Element

Modeling of Mechanical Response in Nacre-Based Hybrid Nanocomposites, J. Theo. Comp. Poly. Sci.

11 (5), pp. 397-404.

|

|

Mineral

Contacts Mineral

Contacts |

|

Modeling

The Organic-Inorganic Interfacial Nanoasperities (Platelet Roughness) RESULTS: The

nanoasperities or surface roughness has small contribution to the

elastic modulus of nacre and almost no contribution to its yield

stress. The roughness may provide better adhesion between organic

phase and the mineral phase and may provide some level of confinement

to the organics.

Katti, D.R., Pradhan, S.M., and Katti, K.S., (2004), Modeling The

Organic-Inorganic Interfacial Nanoasperities In A Model

Bio-Nanocomposite, Nacre,

J. Reviews on Advanced Materials Science, n 6, 162-168.

|

|

|

|

|

|

Red

Abalone

Natural

Nanocomposite: The Seashell

Seashell is a

perfect natural armor

APPLICATIONS

- Design of high performance new

nanocomposites taking inspiration from biological materials

- Development of computational and

analytical tools for a truly simulation based design of materials

- Multiscale models for prediction of

mechanical response of a variety of biological materials for

applications in bioengineering

|

|

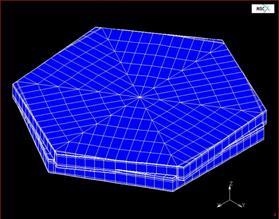

3D Finite Element Simulation of Nacre Micro-Architecture

: Laminated

Structure RESULTS: The elastic

modulus of the organic phase in nacre has a magnitude much higher than that

expected for typical proteins. The simulations predict elastic modulus of

the order of 15 to 20 GPa for the organic phase. (This was later confirmed

experimentally by another group)

Katti, Dinesh R. and Katti, Kalpana S.,

(2001) Modeling Microarchitecture and Mechanical Behavior of Nacre Using 3D

Finite Element Techniques, Part I: Elastic Properties, Journal of Materials

Science,

36 (6):1411-1417

|

|

|

|

Modeling Mineral contacts in

aragonite platelets and relative rotation of platelets RESULTS: The

mineral contacts have minimal contribution to

the elastic modulus and yield stress of nacre. In fact, the mineral

contacts break long before nacre exhibits yielding. It appears the

mineral contacts are present for the biological growth of nacre.

Katti, K.S., Katti, D.R., Tang, J. and Sarikaya,

M.,(2005), Modeling Mechanical Responses In A Laminated Biocomposite,

Part II, Nonlinear Responses And Nuances Of Nanostructure,

Journal of Materials Science, n 40, 1749-1755

|

Scale bar: 50 nm |

|

Discovery of

Interlocks in Nacre: Key to Toughness and Strength

•RESULTS:

Interlocks

accurately predict the observed fracture toughness in nacre when

yield stress of organic is close to that of typical proteins about

5 MPa.

Interlocks predict mechanism of failure:

progressive failure of individual interlocks and large deformation

of organic.

They are the key to why nacre is tough

and strong

Katti, K.S., Katti, D.R., Pradhan, S.M., and Bhosle,

A., (2005), Platelet Interlocks are the Key to Toughness and Strength

in Nacre, Journal of Materials Research, v

20, n5, May, 1097-1100.

|

|