R2 cleanroom labs offer senior design group a venue for producing controller for 3D printer prototype

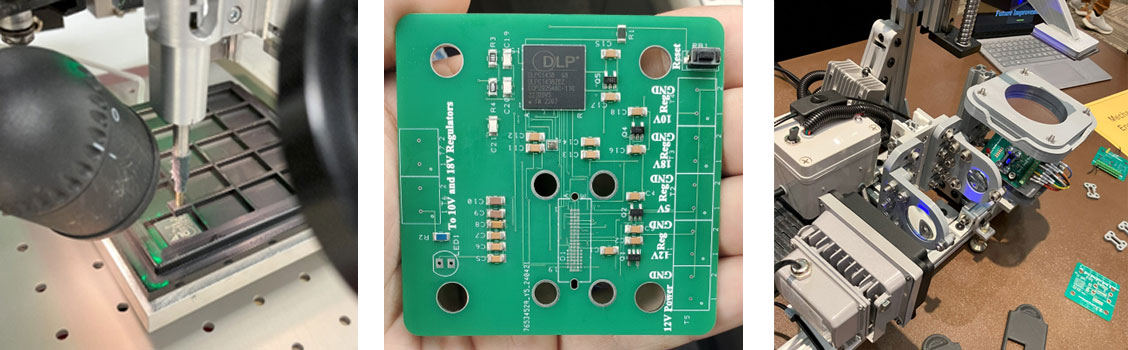

An NDSU senior design group recently utilized technologies at NDSU's Research 2 (R2) facility to help create a DLP-based printer which could print micron-sized materials (-500 micrometer) in various shapes and print fidelity. The group used the R2 Class 10k cleanroom electronics assembly tools to create a functioning circuit board with specific components to control a Micromaterials 3D Printer totally designed and fabricated at NDSU.

Terick Frazer, Joseph Wolf, Joseph Rowland, and Nathan Levorson were members of the team and their printer was showcased at the May 2024 NDSU College of Engineering Spring Senior Design Expo.

Since its inception in 2003, R2 has had a history of offering its teaching, support, and R&D manufacturing services to groups on campus in addition to internal and external customers.

The facility has been used for Department of Defense (DoD) and Defense Microelectronics Activity (DMEA) projects and Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs along with sponsored research and independent research. The class 100k and 10K cleanrooms provide very high-level specific assembly and fabrication processes not normally found at major universities including photolithography, etching processes, chip scale packaging, and surface mount electronics assembly.