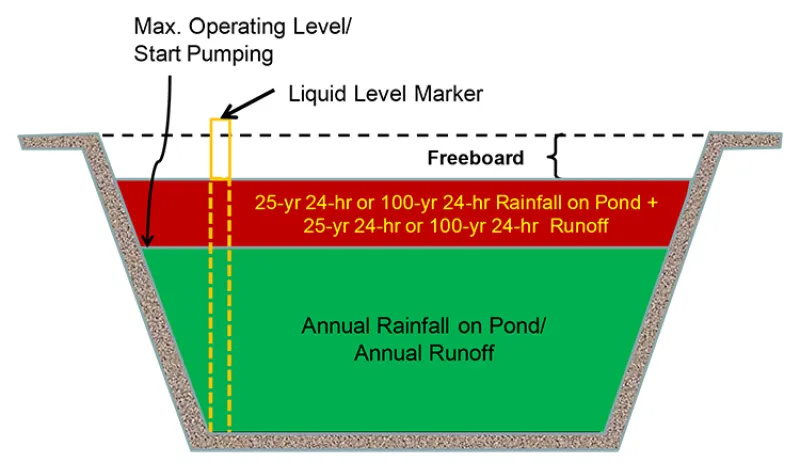

Typically, liquid manure is stored in a manure storage pond or lagoon for six to 12 months. During this period, manure is added to the storage pond on a regular basis. In addition, feedlot runoff and direct precipitation are added to the storage pond.

Permitted animal feeding operations in North Dakota Administrative Code sections 33.1-16-03.1-04 and 33.1-16- 03.1-05 are required to have a liquid level marker or indicator (Figure 2) in earthen manure storage ponds or runoff ponds (North Dakota Livestock Program Design Manual) to help the farmer track and manage manure levels. However, this regulation is ignored or the marker is missing in many situations. As a result, the manure storage or runoff pond may not have enough capacity to take more manure and can overflow.

Inspecting manure storage ponds frequently is a good practice to detect any leakage or rodent/erosion damage to the embankment and alongside pipes, as well as wet areas/seepage on the back slope of a liquid manure storage pond. Any minor repairs (external erosion, small rodent burrows) should be corrected immediately. Otherwise, liquid manure will stress these weak spots and a manure spill will occur. Prevention is always the best means to minimize the risk of manure spills and the resulting environmental damage. Take the following steps to prevent manure spills from storage ponds:

• Install a permanent marker/staff gauge and regularly monitor manure levels.

• Make proper liquid level management a year-round priority.

• Reserve maximum storage capacity for times when open fields are not available/extended wet weather prevents application.

• Pump down the liquid level or take action to remove liquid from storage and properly apply or transfer it to another storage structure when the pond has reached its maximum operating level.

Conducting periodic inspections of embankments can minimize the risk of a storage pond spill. Producers should look for:

• Cracking or holes on the embankment and around pipes

• Wet areas on the back slope

• Erosion

• Rodent or tree damage

If leakage from the base or sidewall of a lagoon or earthen storage structure has occurred, take the following steps immediately to stop additional manure releases:

• Fix weak spots with clay-type soil.

• Create a dam away from the berm or dig a small hole to catch the spill and make cleanup easier.

• Trap or remove burrowing animals if they are causing holes, fill holes and compact them with a clay-type soil.

• Seek engineering assistance.

Modifications or repairs to any pond or storage facility should be done with technical assistance from a conservation agency, such as the Natural Resources Conservation Service or your local Soil and Water Conservation District.

If lagoon/storage pond overflow has occurred, take the following steps to minimize additional manure loss:

• Stop all additional flow into the lagoon and direct the manure to appropriate storage facilities or land apply if weather and conditions allow.

• Lower the volume in the storage pond by applying the liquid to fields at rates provided in the Nutrient Management Plan.

• Make sure no excess surface water is entering the lagoon by checking clean-water diversions (for example, gutters, ditches) and water sources in the barn, such as pipes and watering systems.

• Add soil to the berm to increase the elevation of the dam only with approval of regulatory authorities.