Individual Home Sewage Treatment Systems

(AE892, Revised Jan. 2021)This publication contains information on the design, installation and maintenance of individual home sewage treatment systems. It is meant to be a homeowner reference document. An individual sewage system both treats and disposes of household wastewater. If a homeowner understands how the various components of a home sewage system work, then a properly designed and installed system will function for many years with a minimum of maintenance and upkeep.

Contact your county NDSU Extension office to request a printed copy.

NDSU staff can order copies online (login required).

Home wastewater enters the septic tank, which separates solids from liquids. Solids are held in the septic tank and liquids are conveyed to the final soil treatment site. The septic tank is a “bioreactor” where microorganisms break down organic matter in the wastewater to liquids, gases and solids. Gases are vented off through the house vent stack. Solids are composed of both scum and sludge. Scum is lighter than water and floats to the surface in the septic tank. The solid parts are heavier than water and sink to the bottom of the tank. Bacteria feed on the wastes and the fraction that can’t be decomposed is “sludge.” Sludge accumulates in the bottom of the septic tank and must be removed periodically.

The five parts of a sewage disposal system are: (1) the house plumbing, (2) the sewer line from house to septic tank, (3) the septic tank, (4) the septic tank outlet sewer pipe, and (5) the final soil treatment unit, which may be a soil absorption unit or lagoon. All individual sewage treatment systems must comply with requirements in North Dakota State Administrative Code section 62-03 1-03. City/county health departments or multi-county health districts require a permit before constructing a new home sewage treatment system or when repairing an existing system. During the planning process and before construction, check with your local administrative office that deals with onsite wastewater systems for local requirements.

Whether you need a permit or not, concern for basic human health demands that the location of individual home sewage system components meets certain requirements. For example, keep the septic tank and soil absorption unit at least 100 feet away from any private well that is less than 100 feet deep, and at least 50 feet away from wells more than 100 feet deep. Generally accepted safe distances are shown in Table 1.

| Well less than 100 feet deep | Well more than 100 feet deep | Distribution device | Treatment area | Property lines | Buildings | |

|---|---|---|---|---|---|---|

| Building Sewer | 100 | 50 | -- | -- | -- | -- |

| Septic Tank | 100 | 50 | 5 | 10 | 10 | 100 |

| Distribution Device | 100 | 50 | -- | -- | 10 | 20 |

| Treatment Area | 100 | 50 | 5 | -- | 10 | 10 |

| Well (shallow) | -- | -- | 100 | 100 | NA | NA |

| Well (deep) | -- | -- | 50 | 50 | NA | NA |

| Pressure Water Line | -- | -- | 10 | 10 | NA | NA |

| Suction Water Line | -- | -- | 50 | 50 | NA | NA |

| Surface Water Bodies | NA | NA | 100 | 100 | NA | NA |

| NA - not applicable | ||||||

When the sewage treatment system is installed, make a map of the installation. Measure and record distances from the septic tank, septic tank cleanout and drainfield to aboveground features such as buildings, fence corners or large trees. Then after the area has grassed over, you still can find the component parts of the septic system.

House Plumbing for Sewage

The house plumbing system includes waste pipes, vent pipes and water traps (Figure 1). House plumbing and home sewage treatment systems must comply with the North Dakota State Plumbing Code. Following this code ensures that a plumbing system will be safe and operate properly.

Waste and vent pipes usually are the same pipe, with wastewater flowing downward and gases rising in the pipe. A 3- or 4-inch vertical pipe serves as the main stack to carry wastes, water vapor and gases from the house. The main stack also acts as a vent for gases that collect in the septic tank. Gas from a septic tank has a bad odor, may cause serious illness, and in some situations, can be explosive. In cold weather, the gases exiting from the stack contain water vapor that will form a frost layer that can get thick enough to close off the end of the stack. Excessive snow on the roof also can block the vent stack. Closing off the vent stack will prevent fixtures from draining properly. The vent stack extending above the roof should be insulated to help prevent frost and snow from closing it off.

A water trap must be installed in the drain line between each fixture and the main stack. The trap prevents sewer gases from coming into the house through the fixtures. Without a vent pipe, a full flow of wastewater in the drain line could siphon water out of the traps and let sewer gases into the house. Sometimes, during very windy conditions, wind pressure on the vent stack can force sewer gas through the trap. Proper venting installed according to the plumbing code will prevent this problem.

Adequate cleanouts are necessary in the stack so the plumbing and sewer line can be serviced and cleaned. One cleanout should be installed at the base of the stack and a second at the point where the sewer line leaves the house. One cleanout may be enough if the stack is near the point where the house sewer leaves the building.

Cast iron or copper drain systems may be found in older homes. Most new homes use plastic sewer pipe listed in the plumbing code. When working in older homes, avoid direct copper to iron pipe connections since pinhole leaks may develop in the iron due to galvanic action. Use insulated connectors between copper and iron pipe to reduce this problem.

House sewer pipe should have a slope between 1 percent and 2 percent. This is around a 1- to 2-inch drop in 8 feet. On too flat a grade, the liquid will slow down, allowing the solids to settle out in the sewer pipe. On too steep a grade, the liquids will flow away from the solids.

The sewer line from the house to the septic tank may be plastic sewer pipe with glued joints or cast iron with stainless steel clamps or leaded joints. If using plastic pipe, the pipe must have a pressure rating equal to Schedule 40 or greater. The joints must be glued so they are watertight and resist root penetration.

The house discharge sewer must be at least 4-inch diameter pipe. This pipe must have a uniform slope with no high or low spots. A common place for frost to accumulate in the house discharge sewer pipe is just after the pipe passes through or under the basement wall. Where the house sewer pipe is above the frost line, this problem can be corrected by putting 2-inch-thick rigid foam insulation over the pipe during the installation process. The rigid foam insulation should extend at least 1 foot on either side of the pipe. Insulation generally is not needed if the house sewer is more than 4 feet below the ground surface.

Don’t make sharp bends in the house sewer system. When 45- or 90-degree bends are necessary, use long sweep (long radius) elbows to allow a plumber’s snake to get through the sewer line. If long sweep elbows are not available, use several 22- and half-degree elbows.

Never, under any circumstances, allow basement footing drains to discharge into the house sewage system. This water will overload the septic system. It can cause the water and sewage to back up into the house. Run basement footing drain water to a sump. Install a sump pump and pump the water out away from the drainfield.

Septic Tanks

Septic tanks have been used for on-site wastewater treatment for more than 120 years. A septic tank can have single or multiple compartments. Single- and two-compartment septic tanks generally are used with individual home sewage treatment systems. Household wastewater enters the septic tank through the house discharge sewer pipe (Figure 2). After passing through the inlet baffle, the solids separate from the liquid as the sewage flows slowly through the septic tank. Some solids settle to the bottom of the tank and others float in the scum layer at the top. Bacterial action partially decomposes the solids.

The material in the septic tank separates into three distinct layers:

- A top layer of floating scum

- A middle liquid zone

- A bottom layer of sludge

The scum layer consists primarily of cooking fats and oils, soap scum and products of decomposition that are lighter than water. The greatest amount of bacterial action occurs in the sludge layer, which consists of solids heavier than water.

The liquid discharged from a septic tank is called effluent. Effluent from a properly maintained septic tank is slightly cloudy and contains fine suspended solids, bacteria and nutrients. Septic tank effluent must not be discharged directly to the ground surface or into surface waters. Professional sanitarians call effluent on the ground surface “day lighting.” Human effluent on the ground surface can be a source of dangerous water-borne diseases and produce offensive odors. The effluent must be delivered to a properly designed and constructed drainfield or lagoon for treatment.

All household wastewater must go to the septic tank. Household wastewater sometimes is referred to as “black water” or “gray water,” depending on which appliance or fixture it came from. No matter the source, do not let water and other similar wastes bypass the septic tank. Grey water containing soap or grease sent directly to a drainfield will plug the soil pores quickly.

Sizing

Septic tanks are rated according to liquid-holding capacity, not total capacity. The liquid capacity of a septic tank is the volume of effluent it holds below the tank outlet. Liquid capacity often is called the “working capacity” of a septic tank. For a house, the required working capacity is based on the number of bedrooms, not the number of people in the house at the time of construction. Each bedroom can hold two people, so the standard three-bedroom house could have six people generating household wastewater.

| Number of Bedrooms | Minimum Working Capacity* (Gallons) | Minimum Working capacity for Homes with Garbage Grinders# (Gallons) |

|---|---|---|

| 3 or less | 1,000 | 1,500 |

| 4 | 1,250 | 1,750 |

| 5 | 1,500 | 2,000 |

|

* Working capacity is the tank volume below the outlet. An additional internal volume equal to 20 percent of the working capacity is needed for floating scum storage. # Garbage grinders require septic tanks with about 50 percent greater volume and often a second compartment is required. |

||

Location and Installation

The septic tank should be at least 10 feet away from the house. The tank should be aligned straight out from the point where the discharge sewer line leaves the house. Installing the tank so it is level, with no slope in any direction, is important. For pumping and cleaning, the septic tank should be situated near a driveway or other access road. Most septic pump trucks carry between 50 and 100 feet of hose, so the tank should be accessible from this distance. Select a location away from high vehicle traffic areas. Never locate septic tanks under sidewalks or patios where the tank is inaccessible for pumping.

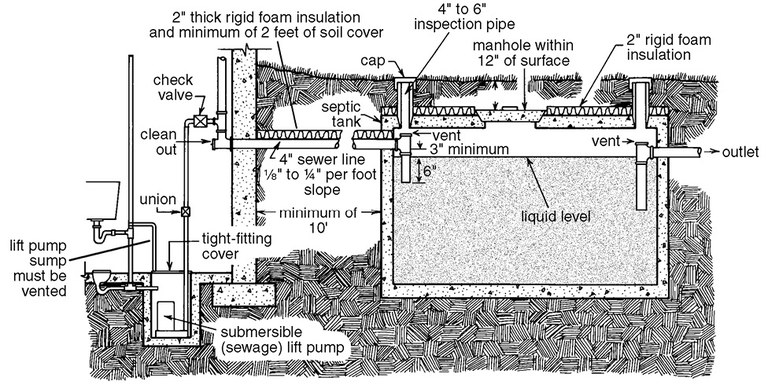

A home sewage treatment system works best and is more easily maintained if both the septic tank and drainfield are near the ground surface. A shallow septic tank and drainfield provides easy access to the component parts, plus the drainfield is more efficient at treating effluent. For new houses, the North Dakota Plumbing Code recommends using a basement sump (Figure 3) designed to handle wastewater if the septic tank and drainfield can work by gravity and the home has basement toilets and fixtures. For these types of systems, the sewer pipe leaves the house through the basement wall. The sump lifts the water to the sewer pipe. If the house sewer pipe is less than 4 feet below ground surface, it needs to be insulated in the trench for frost protection. Ready-to-install basement wastewater sump stations are available in most home supply or hardware stores.

Having the lift pump in the basement has some major advantages. First, that allows the wastewater from the upper part of the house to flow by gravity to the septic system. This has proven to be valuable during a flood or power outage. Second, the homeowner doesn’t need a lift station that pumps all the effluent from a house. Third, a basement sump only turns on when basement fixtures are used. Last, it’s accessible for maintenance and repairs.

Many older houses have a septic tank installed lower than the basement floor level. New houses can have a deep septic tank, providing a high water table is not present (Figure 4). If suitable slope is not present, a lift-pump station must be installed at the outlet side of the septic tank so the drainfield can be installed at a shallow depth. In areas where the water table can rise above the top of the septic tank, homeowners must seal around the inlet and outlet pipe holes, any joints, the septic tank cover and manhole access so they are watertight.

Wastewater from the house and bacterial action usually provide enough heat to keep the septic tank from freezing, even when located above the frost depth. When the top of a septic tank is installed within 2 feet of the ground surface, covering the top of the tank with 2 inches of rigid foam insulation board will help retain heat in the septic tank. Whenever the system is built above frost depth, laying all sewer pipes at a uniform grade with no high or low spots is very important.

Construction

Septic tanks are built using corrosion- and decay-resistant materials. If installed properly, they will be watertight for a long time (30 years or more). Precast reinforced concrete tanks are the most common. However, tanks also may be constructed using poured-in-place concrete or built from concrete blocks with the cores filled with concrete reinforced with rebar. Concrete block tanks must be sealed with at least two coats of concrete plaster. Fiberglass and durable plastic septic tanks also are available. They must be installed by carefully following the manufacturer’s instructions so they will withstand soil and water pressure.

Septic tanks should be designed for a liquid depth of not less than 3 but not more than 6 1/2 feet. The horizontal distance between the inlet and outlet of rectangular tanks should be about three times the width of the tank. Incoming solids will settle out in this distance and not flow out to the drainfield. Circular tanks should have at least a 5-foot inside diameter.

The liquid depth in a septic tank is the distance from the outlet pipe to the bottom of the tank. The septic tank inlet should be at least 3 inches above the outlet. The tank must have room above the liquid level for scum accumulation. A minimum of 20 percent of the tank’s liquid depth should be left as freeboard between the outlet level and the cover of the septic tank. For most manufactured tanks, this will be about 12 inches.

Inlet and Outlet Baffles

Inlet and outlet baffles are critical parts of a correctly installed septic tank (Figure 2). The inlet baffle directs incoming sewage downward into the liquid zone of the septic tank. The outlet baffle allows sewage effluent to flow out of the liquid zone, retaining the scum in the tank. Many new septic tanks have a removable filter incorporated into the outlet baffle. The filter prevents nondecomposable materials (condoms, sanitary napkins and other items) from reaching the drainfield.

Baffles may be constructed as an integral part of the septic tank or fastened to the tank after construction. Four-inch diameter plastic tees often are used as baffles (Figures 2, 3 and 4).

Baffles must be durable and corrosion-proof. Durable concrete, fiberglass or plastic are excellent materials. Never use steel baffles, as they will corrode quickly. If baffles are bolted in place, use only stainless steel bolts.

The bottom of the inlet baffle should be at least 6 inches below the liquid surface when the tank is full. The bottom of the outlet baffle should be at least 18 inches below the liquid surface. The top of the baffles must be open and extend no closer than 1 inch to the tank cover. This is necessary for proper venting of gases from the tank.

Access Holes in Septic Tanks

Access to septic tanks is required for inspection and periodic cleaning. One manhole at least 15 inches in diameter must be on the top of the tank. The manhole should have a concrete cover with an earth covering of at least 6 inches, but not more than 12 inches. If the top of the tank is more than 12 inches below ground level, extensions must be attached to the top of the tank to bring the cover within 12 inches of the ground surface. In high water table areas, the extensions and cover must be watertight. If the manhole access is at ground level, it should have a locking bracket or be chained shut with a padlock (Figure 5).

To check the septic tank’s operation, the tank should have two inspection ports, each 4 to 6 inches in diameter. One should be over the inlet baffle and one over the outlet baffle (Figure 2). This allows for easy inspection to determine if sewage is flowing into or out of the tank properly or if plugging has occurred. The inspection ports must be capped at or just above ground level. The caps prevent gas from escaping and children from dropping objects into the tank.

Septic tanks must be cleaned regularly to remove the sludge that accumulates in the bottom of the tank. Note that the manhole, not the inspection ports, must be used for cleaning the tank. For most houses, cleaning every three years is satisfactory. However, a house with a garbage grinder that the occupants use may require a one- to two-year cleaning interval. Garbage grinders increase the organic matter flowing into the septic tank.

Holding Tanks

Some houses are in areas where a septic tank and drainfield will not work. Locations with a high water table, bedrock close to the surface and very small lots with insufficient drainfield area are the most common reasons. Often the only option is to use a holding tank for household wastewater (Figure 6). People with holding tanks must practice good water conservation so the tank doesn’t fill quickly. Holding tanks have to be pumped on a regular basis, and reducing daily water use in the house will contribute to lower annual pumping costs.

The holding tank must be watertight and hold at least 400 gallons for each bedroom in the house. However, for any house, the minimum tank size should hold at least 1,000 gallons. For a common three-bedroom house occupied by four people, a 1,200-gallon tank will provide about six to 10 days worth of storage. The holding tank must be situated so it is accessible to a pump truck under all weather conditions and where accidental spills during pumping will not create a nuisance. The tank must be level and placed on firm, settled soil capable of bearing the weight of a full tank. The riser of a holding tank must come to the surface. The cover must have a lock or be chained shut to prevent children or other unauthorized individuals from entering it (Figure 5).

Since the tank is watertight, it could try to float out of the ground right after being pumped if the local water table is within 3 feet of the ground surface. In locations with high water table conditions, earth anchors may be necessary. Keeping the tank above the water table and pumping sewage from the house if necessary usually are best.

Installing a meter to measure water flow into the house, and thus the amount of water flowing into the holding tank, may be necessary. By periodically checking the water meter, you will be able to determine when the tank is full. A better method would be to use a high-water alarm. These can be either electronic with a remote reader in the house or a floating indicator that protrudes above ground surface.

Pumping Stations

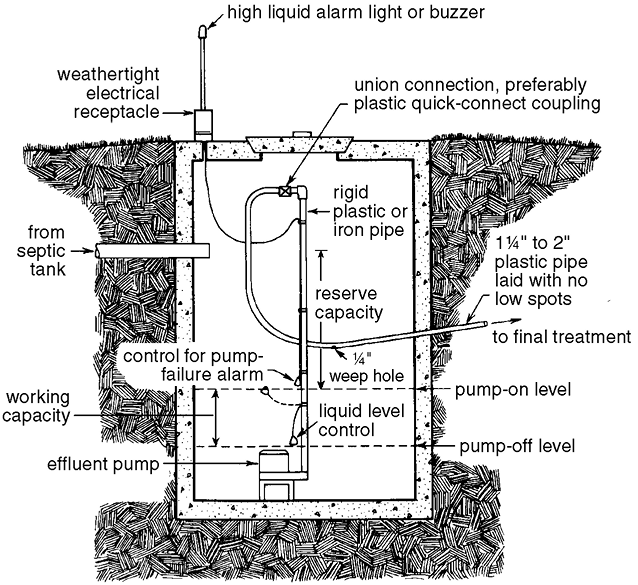

Pumping stations are required in situations where the effluent cannot flow by gravity and must be lifted to a destination. Many new houses are using lift stations in the basement, and outside the house the wastewater flows by gravity through the septic tank to the drainfield. Many manufacturers make complete ready-to-install pump stations for basements. Many older on-site systems have pumping stations that pump all the water coming from a septic tank to the drainfield (Figure 7). Pumping is required with a deep septic tank installation and shallow soil absorption unit or when the soil absorption unit is at a higher elevation than the septic tank. A mound soil absorption system will require a pumping station. A pumping station consists of two main parts — the watertight tank and the pumping system that includes the pump, on/off switches, alarm system and wiring.

Tanks

The tank containing the pump must be watertight. If not, ground water may seep into the tank and the excess water easily will overload the drainfield. Whether the pumping station is in the basement or outside, the tank should have enough volume below the inlet pipe to hold about a day’s worth of wastewater. The tank should hold about one-fourth the daily wastewater volume between the on and off levels of the pump controls. Some reserve capacity in the pumping tank must be available in case of pump failure. A reasonable reserve capacity is three-quarters of the daily estimated wastewater volume.

For example, a three-bedroom house with a design volume of 450 gallons per day (gpd) requires a tank with a working volume of about 110 gallons (volume between pump-on and pump-off) and a reserve capacity of about 330 gallons. The working volume plus reserve capacity equals about 450 gallons, or one day’s amount of wastewater storage.

Pump controls often have a limited range between the on and off setting. Ranges of 12 inches to 30 inches are common. The following table gives some capacities of circular tanks in gallons per foot of depth.

| Inside Diameter (inches) | Gallons per foot of depth |

|---|---|

| 18 | 13 |

| 24 | 23 |

| 30 | 36 |

| 36 | 53 |

| 42 | 72 |

| 48 | 94 |

| 60 | 147 |

| 72 | 212 |

The capacity of rectangular tanks in gallons per foot of depth can be calculated by multiplying length in feet by width in feet by 7.5. For example, a rectangular tank with an inside width of 4 feet and inside length of 5 feet has a capacity of 4 x 5 x 7.5, or 150 gallons per foot of depth. With a 12-inch on-off setting for the pump, this tank would handle a three-bedroom house easily. A circular tank would need a diameter of at least 48 inches, but if the on-off setting were 30 inches, a 30- to 36-inch diameter tank could be used.

Pumping station tank materials include concrete (similar to holding tanks), concrete culvert sections and complete, ready-to-install plastic units. Metal tanks do not last very long because effluent is very corrosive. Installations with an open bottom, such as concrete culvert sections, must have a watertight, cast-in-place concrete floor. All joints between culvert sections must be sealed so they are watertight. Flotation may be a problem with precast tanks under high water table conditions. Under this condition, soil anchors may be required to prevent upward movement.

A secure manhole cover must be located on the top of the pumping tank. The cover must be lockable to prevent children from removing the cover.

Sewage Pumps

Many manufacturers make lift pumps specifically for sewage effluent. Lift pumps must be durable and corrosion-resistant with sealed motors and electrical connections. They must be able to withstand the acidic and corrosive environment present in sewage tanks. Sump pumps sold in home supply and hardware stores for basement drain water are not recommended for use in sewage lift stations. Pedestal sump pumps with an open motor should not be used except in an emergency.

All lift pumps are designed to be submersible. Pump bodies are commonly made from cast bronze, cast iron and plastic. All bolts, nuts and screws are stainless steel. The pump must be set on a concrete block or pedestal in the tank bottom so grit and other solids are not drawn into the pump and sent to the drainfield.

Pump capacity is rated by how much flow rate can be produced versus the amount of head (vertical lift plus friction losses) it is lifting. For example, a pump with a 3/4 horsepower motor might pump 40 gallons per minute (gpm) against a lift of 15 feet. With a lift of 25 feet, the same pump will have a flow rate of only 15 gpm.

Flow rate usually is not a limiting factor in pump selection when pumping to trenches or an absorption bed. However, the maximum lift capability of the pump may be a limiting factor. Always determine the vertical lift by measuring from the pump discharge to the pipe outlet in the drainfield. Select a pump with a maximum lift capability at least 5 feet higher than this elevation difference. Use a 1¼-inch or larger diameter flexible plastic pipe from the pumping station to the drainfield. The plastic pipe must be buried below frost depth with a uniform grade back to the pumping chamber. In the winter, the water in the line should drain back to the pump station to prevent freezing. Low spots in shallow buried pipe will freeze.

When choosing a pump for a mound soil absorption system, size the pump for a delivery of about 7.5 gpm per 100 square feet of rock bed area. For example, a mound for a three-bedroom house has about 300 square feet of rock bed area, so the pump should have a flow rate around 27 gpm. The pump must have this capacity at the required head. The required head will be the elevation difference in feet between the pump discharge and the mound, plus friction loss in the pipe, plus 5 feet. For mound systems, use a minimum of 1½-inch diameter plastic pipe. At a pumping rate of 27 gpm, the friction loss in the pipe will be about 5 feet of head loss per 100 lineal feet of pipe.

Example: A pump must be selected to lift 27 gpm of effluent from a pump chamber to a mound for a three-bedroom house. The mound is 200 feet from the pump tank and 10 vertical feet above the elevation of the pump discharge. The pump must overcome a head of 10 feet (for elevation difference) + 10 feet (for friction loss) + 5 feet = 25 feet. The chosen pump must deliver about 27 gpm at about 25 feet of head.

Install the pump with a union or quick disconnect coupling near the top of the pump tank. This makes installation and removal of the pump easier. Do not install a check valve in the outlet pipe from the pumping station. If the pump has a built-in check valve, remove it. Loop the outlet pipe with a ¼-inch weep hole drilled at the low point of the loop. The weep hole allows the water in the pipe to drain back to the pump tank after the pump shuts off.

Pump Controls

All wastewater pumps need to be turned on and off based on the liquid level in the tank. The most common pump on/off control is a mercury level control switch sealed in an effluent-resistant plastic or rubber bulb (Figure 8). The length of the cord between the attachment point and the mercury bulb determines the water level where the pump turns on and off.

A licensed electrician must install all electrical wiring for a pump station. Electrical outlets must not be installed inside a pump tank. State plumbing code requires all electrical connections to be outside the pump tank. On/off control switches commonly use piggyback plugs where the control cord plugs into an electrical outlet and the pump electrical cord plugs piggyback into the control cord plug. A weatherproof box outside the pumping tank must be used for an electrical outlet to serve the pump.

Pumps must have a failure alarm system to warn the homeowner if the pump stops pumping. The alarm system senses pump failure when water rises above the pump-on control. The sensor is another mercury level control switch in a watertight bulb. It usually is set 3 to 6 inches higher than the pump-on water level sensor. The pump failure alarm circuit should be installed on an electrical circuit separate from the pump.

A homeowner can select from among several alarm methods to warn of pump failure. Remote alarms, located in a convenient place in the house or garage, are common. They can be programmed to make a sound similar to a smoke detector, flash a light or call a telephone number. Many alarms are at the pump tank on a pole and use either a light or buzzer to warn of pump failure. Some use a light aimed at a window in the house.

Septic Tank Outlet Sewer

The outlet sewer pipe carries sewage effluent from the septic tank to a pump chamber or the drainfield. The outlet sewer pipe must be watertight where it leaves the septic tank and at least 4 inches in diameter. Plastic pipe (either PVC or ABS) should be schedule 40. Plastic pipe with thinner wall thickness often will slump when the soil settles. Lay the pipe at a minimum grade of 1/8 inch per foot. No maximum grade is required for the outlet sewer pipe since it carries only liquid. The outlet sewer pipe must be laid to grade with no low spots where effluent can collect and freeze.

Soil Absorption Systems

The soil absorption system has to work all year. That means it must infiltrate effluent during wet springs and cold winters. Effluent from the septic tank is about 99 percent water but it also contains biological material (small particles). Additional treatment of the biological material occurs in the soil absorption system (Figure 9). The area of soil absorption must be sized so it can infiltrate the daily wastewater flow from the house, as well as effectively decompose the biological materials in the effluent.

The ability of the soil to treat and infiltrate the effluent is based on the texture and local hydrology at the depth where the effluent will be introduced to the soil. In the past, a “percolation” test was performed and the results were used to size the soil absorption system. The infiltration rate of the soil usually was given in “minutes per inch” or mpi. The lower the mpi, the higher the infiltration rate. However, percolation tests have proven to be unreliable in many situations. Currently, many local health districts require a registered soil classifier to determine the texture of the soil and local groundwater hydrology for design purposes. Percolation tests still are accepted in some health districts or if a house lot has been created with fill soil. The procedure for doing a percolation test is in Appendix A.

Absorption Trenches

Trenches are the most common and effective drainfield. They can be used in areas where the historic high water table is at least 24 inches (2 feet) below the trench bottom. However, 36 inches or more of separation between the high water table and trench bottom is preferred. Trenches are most suitable for soil textures with percolation rates of 60 minutes per inch (mpi) or less (Table 3). Trenches may be used on 61 to 90 mpi soils, providing a high water table does not exist and adequate trench length is used. For soils with percolation rates of 61 to 90 mpi, increase the trench area by 25 percent over the area required for a soil with a 60 mpi percolation rate. For soils with percolation rates greater than 90 mpi, trenches should not be used as a soil absorption system without consulting the local health sanitarian.

| Depth of rock below the distribution pipe | |||||

|---|---|---|---|---|---|

| Soil Texture | Percolation Rate (minutes/inch) | 6" | 12" | 18" | 24" |

| Square feet of trench bottom per bedroom | |||||

| Sand and loamy sand | 1 to 5 | 125 | 100 | 85 | 70 |

| Sandy loam | 6 to 15 | 190 | 150 | 125 | 110 |

| Fin sand, very fine sand, loam | 16 to 30 | 250 | 200 | 165 | 145 |

| Silt and silt loam | 30 to 45 | 300 | 240 | 200 | 170 |

| Clay loam, sandy clay, silty clay loam | 45 to 60 | 330 | 265 | 220 | 190 |

| Clay | 60 to 120 | 650 | 515 | 440 | 375 |

| Trench bottom area loading rate, gal/ft2/day | |||||

| Sand and loamy sand | 1 to 5 | 1.2 | 1.5 | 1.8 | 2.1 |

| Sandy loam | 6 to 15 | 0.8 | 1.0 | 1.2 | 1.4 |

| Fine sand, very fine sand, loam | 16 to 30 | 0.6 | 0.75 | 0.90 | 1.05 |

| Silt and silt loam | 30 to 45 | 0.5 | 0.63 | 0.75 | 0.90 |

| Clay loam, sandy clay, silty clay loam | 45 to 60 | 0.45 | 0.57 | 0.68 | 0.80 |

| Clay | 60 to 120 | 0.23 | 0.29 | 0.34 | 0.40 |

The square footage (length and width) of required absorption trench for a given house and lot is based on the daily average wastewater flow and soil texture at the depth of the trench bottom. If the soil texture is a mixture, for instance a fine sand with some silt mixed in, design for the finer soil. Be sure to construct at least this amount of absorption trench. Many homeowners and installers feel this is more trench than they require and install less trench to save money. This usually ends up being false economy. The system fails within a number of years and then additional work must be done to upgrade the system. Recommendations for trench bottom area are based on a long-life treatment system, not a temporary solution. Built into the trench bottom area requirements is reduced infiltration capacity through time due to the accumulation of biological material in the trench bottom.

Trench Construction

Trenches are constructed with a backhoe. Commonly, a 24- to 36-inch-wide bucket is used. A wider bucket makes a wider trench that increases the trench bottom area and reduces the length of trench. Do not allow any wheel tracks in the trench since the compaction will seal the surface, greatly reducing the effectiveness of the absorption trench.

The bottom of each trench must be level throughout its full length. A level trench bottom allows effluent to infiltrate uniformly for its entire length. If the trench bottom has any slope, all the effluent will collect at the low spots. This can lead to premature failure or day lighting of effluent. In most situations, the maximum length of any one trench should not be more than 100 feet from the point where effluent enters the trench. A trench can be 200 feet long if the effluent is delivered to the center. On sloping ground, trenches must follow the contour of the slope so the bottom of the trench is level along its full length (Figure 10).

Never construct trenches in loam or clay loam soils under wet conditions. At the depth where the trench bottom will be, obtain a soil sample and the soil wetness. If the soil can be rolled into a thread 1/8 inch in diameter without breaking, it is too wet to dig trenches. Wet soil will compact and smear, sealing the trench and greatly increasing the chance of failure. If the soil is dry enough for construction, it will crumble when you try to roll it into a thread.

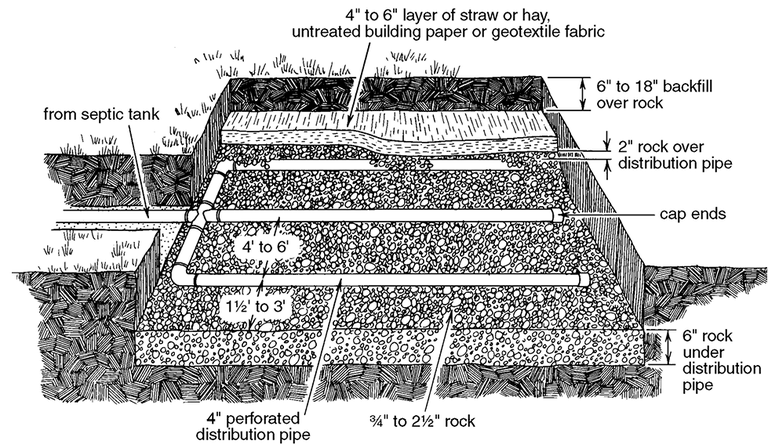

Rock-filled Trenches

Trenches using crushed rock for overburden support may be constructed 18 to 36 inches wide and 6 to 48 inches deep. The depth of crushed rock is dependent on the depth of the trench (Figure 11) and distribution pipe. In the trench, use ¾- to 2½-inch diameter crushed rock that has been washed (some suppliers call it drainfield rock). Washed rock is important because most rock has fine clay attached. When unwashed rock is used, the clay will be washed off by the effluent and end up in the bottom of the trench. This can reduce the infiltration rate and lead to premature failure. The depth of soil cover over the rock will depend on the depth of the distribution pipe.

Four-inch diameter plastic sewer pipe with ½-inch diameter or larger holes spaced 12 inches apart or closer is used for distribution pipe (Figure 12). It is available in home supply and hardware stores. The distribution pipe can have a slight slope (1- to 2-inch drop in 100 feet) to help distribute the effluent over the full length of the trench. The pipe should have at least 2 inches of crushed rock over it. The rock under the pipe distributes effluent over the trench bottom and sidewalls, allowing the liquid to infiltrate into the soil. The pipe is oriented in the trench with the holes downward. When using pipe with a double row of holes, place the pipe with the holes downward in a 5 o’clock and 7 o’clock position.

The rock must be covered to prevent soil from seeping in and plugging the spaces between the rocks (Figure 13). Several products can be used. The most common is red rosin paper or a geotextile fabric. A 4- to 6-inch layer of hay or straw also can be used. Don’t use plastic (black or clear) to cover the rocks in the trench. After covering the rock, backfill the trenches with earth. Overfill the trenches with 4 to 6 inches of backfill to allow for settling.

Gravelless Trenches

Gravelless trench systems use plastic pipe or chambers (Figures 14 to 17) instead of crushed rock for overburden support. No rock is required in the trenches with these products. Gravelless systems are becoming more common because they can be installed with a smaller crew, require less heavy equipment and provide greater effluent storage volume in the trench. Like any trench system, the trench bottom must be level for good distribution of effluent.

Trench bottom area is determined from Table 3 using the 6 inches of gravel column. Both the pipe and chamber system designs use an equivalent of a 3-foot-wide trench. For example, say we want to install a gravelless trench system for a three-bedroom house with a silt loam soil at the bottom of the trench. From Table 3, the necessary bottom area would be 300 square feet per bedroom for a total of 900 square feet. Using an equivalent trench width of 3 feet requires 300 feet of trench. We could put in three trenches each 100 feet long or four trenches each 75 feet long.

The gravelless pipe system uses plastic corrugated pipe covered with a nondegradable geotextile fabric sock. It can be installed in trenches a minimum of 18 inches wide to a maximum depth of 4 feet. The outside diameter of the pipe is 12 inches, which provides a circumference of just more than 3 feet. This is equivalent to a 3-foot-wide trench because the biomat treatment area forms on the sock on the outside of the pipe and increases the infiltration area. The chamber system also has a maximum burial depth of 4 feet. The chamber design has various permutations that range in width from 18 inches to 3 feet. Selection is based on site requirements and soil texture.

Effluent Distribution

Most trench drainfields have two to four separate trenches requiring some method of equitably distributing the effluent between the trenches. Two methods commonly used are drop boxes and distribution boxes. Drop boxes are used on sloping land where the trenches are aligned with the contour of the slope (Figure 9). Distribution boxes are used on level land where the elevations of all the trench bottoms are about the same.

Drop Boxes

Drop boxes are the preferred method of effluent distribution and may be used on near-level or sloping terrain (Figures 18, 19 and 20). Drop boxes commonly are made from concrete or plastic. They have an inlet, two outlets that distribute the effluent to the trench and an outlet that takes the overflow to the next drop box. The inlet and outlets commonly are 4 inches in diameter to accommodate plastic pipe. Drop boxes allow a trench to be utilized fully before any effluent goes to the next trench. Drop boxes are required for trench systems installed on hillsides. Even distribution of effluent over the entire drainfield is very important. Otherwise, all the effluent would collect in the low spots and overload the soil. If a trench becomes overloaded and effluent is coming to the surface, the outlets from the drop box can be blocked to allow the trench time to recover its ability to infiltrate effluent.

Distribution Boxes

Distribution boxes are used only on level terrain (Figure 21). Distribution boxes normally are made from concrete or plastic. They have an inlet and usually three outlets for each of the absorption trenches. The inlet and outlets commonly are 4 inches in diameter to accommodate plastic pipe. All of the outlets from the distribution box are set at the same elevation, thus having a base under the box of crushed rock or gravel to keep it level is very important. However, in practice, due to frost action or flooding conditions, keeping all outlets at the same elevation throughout the life of the system is virtually impossible. If the box gets tilted, the trench served by the lowest outlet will receive the greatest amount of effluent. For this reason, distribution boxes may be used only where the elevation of the lowest trench is high enough to back effluent up to the distribution box without surface seepage occurring.

A common sign of problems with a distribution box is if the soil gets soggy over one trench but stays dry over the others. To check for this problem, open the top of the distribution box and check the water flow to the outlets. You may have to dig around the box and level it again. After leveling the box, the outlet going to the trench that was soggy can be plugged temporarily (two to four weeks) so the trench can be rested.

Absorption Beds

Absorption beds basically are rectangular pits dug into the soil (Figure 22). Depending on the house lot, depths can range from 1 to 4 feet. They cannot be used in locations having slopes greater than 6 percent. Absorption beds are not as effective at treating effluent as trenches because the absorption bed has less sidewall area for infiltration. Therefore, about 25 percent to 50 percent more bottom area is required than for trenches. Even with the larger bottom area requirement, absorption beds require less total yard area than trenches and can be used on small house lots. Soil texture and the number of bedrooms in the house determine the necessary bottom area of an absorption bed (Table 4).

| Soil Texture | Percolation Rate (minutes/inch) | Loading Rate gal/ft2/day | Bottom Area Per Bedroom* square feet |

|---|---|---|---|

| Sand and loamy sand | 1 to 5 | 1.0 | 150 |

| Sandy loam | 6 to 15 | 0.65 | 230 |

| Fine sand, very fine sand, loam | 16 to 30 | 0.5 | 300 |

| Silt and silt loam | 30 to 45 | 0.40 | 375 |

| Clay loam, sandy clay, silty clay loam | 45 to 60 | 0.35 | 430 |

| Clay | 60 to 120 | 0.18 | 830 |

| * Based on 150 gallons per day per bedroom | |||

The absorption bed should be dug with a backhoe. No wheeled or tracked equipment should be driven on the bottom of the bed. The bottom of the absorption bed must be level in all directions. A minimum of 6 inches of rock should be placed in the bottom of the bed. Use washed rock that is ¾ to 2½ inches in diameter. The rock must be washed to remove clay particle. When unwashed rock is used, the clay will be washed off by the effluent and end up in the bottom of the bed. This can reduce the infiltration rate and lead to premature failure.

The pipes within absorption beds are normally 4-inch diameter perforated plastic. The pipes must be level, 4 to 6 feet apart and 1½ to 3 feet from the edge of the bed. The pipes normally are joined at the ends to form a continuous loop, although they can be terminated as shown in Figure 22. A four-way tee will distribute the effluent but a distribution box also can be used. All joints must be glued. Washed rock then is placed over the distribution pipe to a depth of 2 to 4 inches. After the distribution pipe is covered with rock, a soil separator must be placed above the rock. Any of the following materials are acceptable: a 4- to 6-inch layer of hay or straw, untreated building paper (called red rosin paper) or a geotextile specifically designed for drain fields. Cover the bed with 6 to 18 inches of topsoil and form a crown to account for any settling and also allow the bed to shed water. Shallow absorption beds often will have a permanent mound. Don’t plant trees or shrubs on top of the absorption bed.

Sewage Mounds

Sewage mounds can trace their origins to the first “NODAK” mounds that J. Clayton Russell and Richard Witz designed in 1947 at North Dakota State University. Through the years, the design parameters and shapes of mounds continually have changed as more research information became available. Present parameters for mound design allow for higher water usage and different construction techniques than many earlier designs.

A sewage mound is a special drainfield design used in locations with high water tables (within 2 to 3 feet of the surface) and slow infiltration rate soils. A sewage mound takes advantage of the higher infiltration rate of surface soils, compared with subsurface soils. A sewage mound is constructed above the existing ground surface. A mound is basically a high infiltration rate bed set on top of a sand fill that has been spread over the existing ground (Figure 23). The high infiltration rate bed can be constructed using clean rock or gravelless systems (Figure 24). The area where sand makes contact with the existing ground is called the basal area. On low infiltration rate soils, the basal area must be large enough to allow percolation of the daily effluent volume into the soil surface. In high water table conditions, the elevated bed allows biological treatment to take place before the effluent infiltrates to the water table.

Effluent is pumped to a mound system and distributed across the rapid infiltration bed under pressure (Figure 25). The effluent is pumped to the mound through 1½-inch diameter or larger plastic pipe. The pump tank should be large enough and the pump controls set so a dose equal to about one-fourth of the daily wastewater volume is discharged to the mound when the pump starts. A three-bedroom house has a design load of 450 gpd, so the pump should discharge about 110 gallons per dose. This provides a rest period between doses and allows the effluent to infiltrate before the next dose. In addition, it increases pump life. Frequent starting and stopping of a pump will reduce the life of the motor.

Sewage mounds always should be designed with a pressurized effluent distribution system (Figure 26). A pressurized distribution system evenly distributes the effluent over the entire basal area and helps prevent overloading in any one spot under the mound. The plastic pipes can be set in either a rock bed or inside gravelless pipe. Gravelless pipe manufacturers make products specifically for use in sewage mounds.

The pressure distribution system is constructed from either 1¼- or 1½-inch PVC pipe. Pipe diameter is important because too large a diameter (such as 2 inches) could result in uneven distribution of the effluent. For a sewage mound requiring a 6-foot or narrower rapid infiltration area, two parallel pipes are used. For a sewage mound requiring a 7- to 10-foot-wide rapid infiltration area, three parallel pipes are used. When using plastic gravelless systems instead of rock, the pressure distribution pipe is attached inside the chamber or pipe.

The distribution pipes must have a ¼-inch diameter hole every 40 inches in the bottom of the pipes. The pipe joints and end caps must be glued. Otherwise, they will pull apart during construction, under pressure or later from settling and frost heave. The pipes are connected at the center where the effluent enters the pressurized distribution system from the pump delivery pipe. To protect from freezing conditions, the distribution pipe and delivery pipe must be designed to drain when the pump is off. This can be accomplished by using a ¼-inch diameter weep hole in the delivery pipe in the pump tank.

Sizing

The basal area of the mound (contact area of the fill sand with the existing soil) determines all the other mound design parameters. The basal area is determined by the texture of the existing soil. For slowly permeable clay and clay loam soils, use a design effluent loading rate of from 0.20 to 0.25 gallon per day per square foot.

Example: for a three-bedroom house producing 450 gallons per day of effluent, the contact area between the fill sand and the existing ground should be between 1,800 feet2 (450 gpd ÷ 0.25 gpd/feet2) and 2,250 feet2 (450 gpd ÷ 0.20 gpd/feet2). Figure 27 shows a mound for a three-bedroom home. The basal contact area for this mound on level ground is 2,150 square feet. The amount of clean, washed sand needed is about 72 cubic yards.

The rapid infiltration area is determined using the intake rate of medium sand. Medium sand has a loading rate of 1.2 gallons per day per square foot. Using the three-bedroom home example, the required rock bed area is 375 feet2 (450 gallons per day ÷ 1.2 gallons/day/feet2). If a gravelless system is used instead of rock, it needs to be sized to provide 375 feet2 of rapid infiltration area. For soils with low permeability, keep the effluent distribution pipe width at 4 to 6 feet. For our three-bedroom home example, the rock bed or gravelless systems will be about 375 feet2 ÷ 6 = 63 feet long. A 6-foot-wide rock bed 12 inches thick will require about 14 cubic yards of washed rock. For gravelless systems, two rows of plastic chamber or two rows of gravelless pipe, each 63 feet long, are required.

Mounds should be located on flat areas or the crests of hills; however, they can be built on sloping terrain (Figure 28). However, soil texture and percolation rate will determine the maximum slope. For example, if the soil texture of the topsoil is clay loam with a percolation rate of 120 mpi, then the ground slope should not exceed 3 percent (3-foot vertical drop in 100 feet). If the percolation rate is between 60 and 120 mpi, then the ground slope should not exceed 6 percent, and if the percolation rate is 30 mpi or less, then mounds can be constructed on slopes up to 12 percent.

When a mound is constructed on a slope, only the sand-soil contact area under the distribution area (rock bed or gravelless) and down-slope from there can be considered basal area. Under sloping soil conditions, the ends and up-slope portion of the mound receive very little effluent and do not contribute to the area of infiltration.

Construction

Mounds require very diligent and careful construction practices. Mounds have been known to fail due to two main causes — too small of a basal area for the effluent flow from the house, and poor construction practices. To ensure a mound works as planned, construction practices must be followed very closely. Plus, the homeowner must use water wisely.

The first step in mound construction is to mow the grass or vegetative cover over the basal area to a maximum 2-inch height and remove all the cuttings. Then dig in the effluent line from the pumping station. The line must be installed below frost level or sloped uniformly back to the pumping chamber so it drains after the pump shuts off. The excavated trench must be backfilled and the soil firmly compacted to prevent effluent from flowing along the pipe.

Ground preparation comes next. The ground must be ripped or scarified with a chisel plow or the teeth from the backhoe bucket. Once the surface is prepared, no wheel traffic can be allowed in the basal area. Wheel traffic will seal the soil. Do not work in wet soil conditions because wet soil will compact, smear and seal the soil.

Next comes the fill sand. The fill sand should be washed and checked to be sure it contains no more than 10 percent fines. To test, put 2½ inches of sand in a quart jar and add water until about three-quarters full. Cover and shake to mix the sand and water. Let the mixture stand for an hour and measure the silt and clay accumulation on top of the sand. If the depth is ¼ inch or less, the sand is clean enough for use in the mound. This test should be done before the sand is delivered to the site. Pit run sand varies widely, even from the same area of a pit, and should not be used.

Place the clean sand starting at one end and work toward the other end. Drive on top of the sand as you progress. Shape the sand with a backhoe with tracks or a crawler tractor but make sure you have at least 6 inches of sand under the tracks. Wheeled vehicles should not be used for this operation. Do not allow the tracks to run directly on the earth. After forming with the tractor blade, level and do the final shaping by hand. The top of the sand bed should be level the full length of the mound.

For rock beds, a trench about 12 inches deep and 6 feet wide should be formed the required length on top of the sand. Place 6 inches of ¾- to 3-inch diameter rock in the trench. Place the pressure distribution pipe on the rock and cover with 2 inches of rock. Cover the rock with one of the following: a 4- to 6-inch layer of hay or straw, untreated building paper (red rosin paper) or a geotextile material designed for septic system drainfields.

For gravelless distribution, place the gravelless pipe or chamber on top of the level sand. Place the distribution pipe in the gravelless carriers and connect to the delivery pipe from the pump tank. Double-check all connections. Test the pump and distribution system before covering. Cover the gravelless system with a geotextile fabric and put a cap of heavy soil on top (Figure 24).

Cap the mound with a loam or loamy sand soil (Figures 23 and 24). Make the cap 12 inches high at the center of the bed and 6 inches high at the end of the bed. Taper the cap down the sides of the mound.

Last, cover the mound with 6 inches of good top soil and seed to grass. Don’t plant trees or shrubs on top of the mound. Water-tolerant shrubs may be planted around the base. Permanent lawn sprinkler systems should not be installed near enough to the mound to throw water on it.

Construct mounds to follow the contour of the existing ground. Never place a mound in a low area where water will accumulate. If the mound is on sloping ground, use a berm on the uphill side to divert runoff water around the mound. Mounds can be constructed to complement your landscaping design. Shrubs at the base of the mound will use water and help trap snow. If the mound is built in the fall, it should be covered with straw or hay the first winter to prevent freezing.

Lagoons

Small lagoons (Figure 29) can be used to contain septic system effluent in some locations. Lagoons are a viable option when the nearest neighbor is at least a quarter of a mile away. Lagoons should be constructed only in high clay content soils. A lagoon should act as a container and not as an infiltration galley. The water in a lagoon should be removed by evaporation.

The lagoon surface area should be sized at about 1,000 square feet per bedroom. A lagoon serving a three-bedroom house needs about 3,000 square feet of water surface area. The lagoon should have a working depth of about 3 feet and a minimum freeboard of 2 feet. The sides of the lagoon should have a 3-1 slope or more. A circular 3,000-square-foot lagoon with 3 feet working depth and 3-1 side slopes would have a 62-foot diameter at its working depth and a 74-foot diameter at the top of the dike. The lagoon also may be square or rectangular.

A lagoon must be fenced to exclude children and animals. Annual maintenance requires checking for damage and to make sure animals are not burrowing into the sides of the lagoon. Cattails and other plants in the lagoon help use the nutrients in the water, but their roots can create channels for water to seep away.

Alternative Septic Systems

Homeowners have many alternative methods for treatment and disposal of wastewater from a house. Some alternative systems replace the septic tank or modify the operation of the septic tank to speed up or improve the initial treatment of the household wastewater. Some alternative methods to the traditional drainfield improve the infiltration of the treated water. Many of these alternative systems are designed as complete packages.

Generally, alternative systems are more expensive than traditional systems and practically all of them require electrical power on a continuous basis. However, in some locations where a traditional septic system cannot be installed, they provide a viable alternative. If you are in a health district with on-site septic system rules, check with your local health sanitarian before installing an alternative system. Some may not be approved. In areas with no sanitarian, check with the North Dakota Health Department’s Environmental Health Section. Some of the more common alternative systems are listed here.

Filtration Systems

Filtration systems physically trap suspended solids in the wastewater and provide a medium to speed up the process of decomposition. They are like mini versions of a typical municipal waste treatment system. Filtration systems can be part of the septic tank or just downstream from the septic tank. Sand filters have been used for many years and they can be configured as single-pass (waste flows through only once) or multiple-pass systems. Filtration systems that use peat have come on the market in the last 10 years and are used as a single-pass system. Other filtration systems use artificial or synthetic materials to filter the effluent and treat the biological solids. These mostly are multiple-pass systems. In some parts of the U.S., artificial wetlands have been used to treat household wastewater. However, research on artificial wetlands in the northern-tier states has not been successful.

Except for some single-pass filtration, all the others have to use a pump to circulate the effluent for multiple passes. Use of a pump on a continuous basis increases energy costs and requires an alarm system. Often the systems cannot be operated unless the pump is working.

Alternative Drainfields

Most alternative drainfields are variations of the trench, absorption bed and mound systems outlined in this publication. At-grade systems are used in high water table areas, areas with shallow bedrock or other infiltration problems. They are a combination of trench and mound technology. The trench bottom is ground surface. The vegetation is removed and the ground is roughed up or scarified where the trench bottom will be. Then gravel is added and the distribution pipes are laid in place and covered with gravel and then a layer of topsoil.

Alternating drainfields is another method of distributing wastewater. Two drainfields are constructed. Each has about 50 percent to 100 percent of the area needed for the house. While one drainfield is in use, the other is resting. Typically, one will be used for about two years, then the homeowner will switch to the other. A special box with a two-way valve or sliding gate controls the flow from the septic tank.

Drip irrigation is being used to distribute treated wastewater in some parts of the U.S. The drip lines usually are buried about 1 foot below the soil surface. Drip lines can plug very easily, so the wastewater must be treated, filtered and chlorinated before it is pumped to the drip lines. These systems can be very expensive both to install and maintain.

Appendix: Percolation Test

Percolation tests are made at locations where the water table is at least 2 feet below the surface or where the drainfield will be constructed in “fill’ soil. The percolation test helps determine the ability of a soil to absorb effluent. The rate of water drop in a test hole determines the percolation rate (Figure 30). A fast drop indicates a high percolation rate while a slow drop indicates slow percolation. Soils that have slow percolation rates need large soil absorption areas to treat a given quantity of effluent.

Figure 30. Soil percolation test hole and water level measuring apparatus.

Prior to running a percolation test, make soil borings to a depth of at least 5 feet to determine the soil texture (amount of sand, silt and clay) at potential locations for the drainfield. Then choose the location with the best soil characteristics. Generally, soils with higher sand content are better choices for the drainfield area. Once a location is selected, dig at least three holes at opposite ends of the site and do a percolation test in each hole.

The following steps outline the procedure used in running a percolation test:

- Dig a 6- to 8-inch diameter hole to the depth of the proposed drainfield. Roughen the sides and bottom of the holes with a knife or nails driven into a board to counteract the sealing action of the spade or auger. Clean out the loose dirt in the bottom of the hole. Place 2 inches of coarse gravel in the hole.

- Carefully pour at least 12 inches of water into the hole. Add water through a hose connected to a funnel. The bottom of the hose should rest on the top of the rock to prevent washing of the soil in the test hole. Washing will loosen fine materials and seal the hole. Keep water in the hole at least four hours (overnight would be better). Refill if necessary to keep the water at the 12-inch level. In clay soils, water must be kept in the hole at least 12 hours for soil swelling to take place before measuring the percolation rate.

- Do the percolation test. Adjust the water level so it is about 6 to 8 inches above the gravel layer. Measure the water level from a fixed point every 30 minutes or as often as required and calculate percolation rate in minutes per inch. The percolation rate is calculated by dividing the time interval in minutes by the water level drop in inches.

|

34 minutes 1-1/8 inches |

= |

30.2 mpi |

Refill the hole as required. Calculate the percolation rate for each reading. Continue taking readings until three percolation rates vary by no more than 10 percent. For example, if you had three readings of 28.4, 27.4 and 29.5 mpi, 10 percent would be about 2.8 mpi, which means they are within 10 percent of each other. Use the slowest value for each test hole to get the average percolation rate for designing the soil absorption field.

| Test 1 | Test 2 | Test 3 | Use | |

|---|---|---|---|---|

| Hole 1 | 28.4 | 27.4 | 29.5 | 29.5 |

| Hole 2 | 31.1 | 32.8 | 33.5 | 33.5 |

| Hole 3 | 33.4 | 34.1 | 32.9 | 34.1 |

| Average | 32.4 |

References

North Dakota State Administrative Code, Section 62-03.1-03, 2000, Private Sewage Disposal Systems.

Design Manual: Onsite Wastewater Treatment and Disposal Systems, 1980. Report number EPA-625/1-80-012, Environment Protection Agency (EPA), Office of Water Program Operations, Washington DC.

Onsite Wastewater Treatment Systems Manual, 2002. Report number EPA/625/R-00/008, Environmental Protection Agency (EPA), National Risk Management Research Laboratory, Cincinnati, OH.

Residential Onsite Wastewater Treatment Systems: An Operation and Maintenance Service Provider Program, 2005. MWPS (Midwest Plan Service), 122 Davidson Hall, Iowa State University, Ames, IA.

Reviewed and reprinted October 2015