Applying fertilizer with the seed at planting is one successful soil management practice that has long been recognized as a means to improve crop yields. Grain drills with fertilizer attachments enable the farmer to apply a small amount of fertilizer with the seed and plant in one operation.

A common practice in the northern Great Plains dryland small-grain production area is to apply 50 pounds per acre of 11-52-0 (N+P205+K20) fertilizer with the seed at planting. This practice is called applying ‘starter fertilizer’, which in small grains improves early root and plant growth in low- to medium-P-testing soils.

The starter fertilizer also has the potential to enhance plant development early in the spring, when soil temperatures are normally low and soil nutrient availability to a young root system is lower.

High small grain yields possible with advances in soil management, improved cultivars and reduced soil organic matter have increased the need for fertilizer, particularly N. Most fields require more fertilizer than can be placed with the seed.

Application of higher rates of fertilizer with the seed at planting often causes severe seed germination damage, resulting in poor seedling emergence, poor stands with a subsequent yield loss. Additional fertilizer (NPK) required for maximum economic yield greater than the limits put forth in this publication should be applied in another operation, either broadcast, or banded away from the seed.

Although the broadcast and band application of fertilizers have been successful soil fertilizer management practices, producers once again are interested in applying higher rates of fertilizer with the seed, especially N. This interest has been driven by a desire to [1] reduce the number of field operations, [2] emphasize conservation tillage to improve soil water management, [3] reduce erosion by maintaining adequate residue on the soil surface and [4] use high-residue seeding equipment such as hoe drills and especially air seeders that utilize a higher portion of the seedbed than the traditional double-disc drill.

The question continually being asked is: How much N can be applied safely with small-grain seed at planting? Many factors influence the actual rate of fertilizer to apply, and these factors may vary with specific environmental conditions and locations.

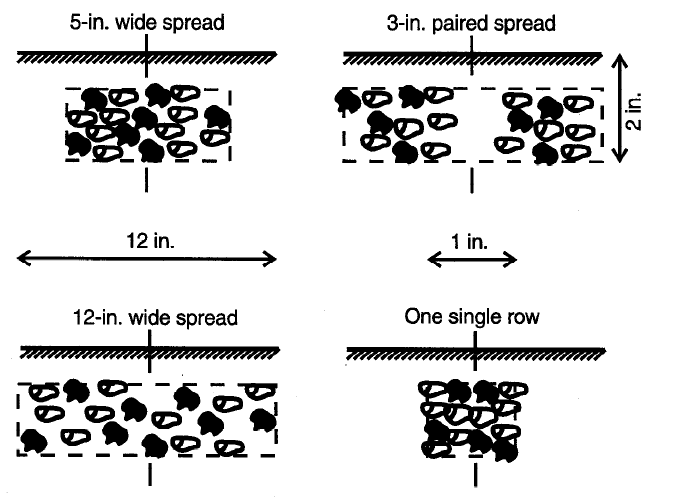

Some site-specific factors that need to be considered when determining the rate of N to apply with the seed include row spacing, seed furrow opener type, seedbed utilized (width of seed spread), soil texture, soil pH, soil water, precipitation, fertilizer placement, fertilizer form, fertilizer material and crop.